What is Air handling unit?

Air handling unit is a part of HVAC system (Heating ventilation and air conditioning system)Air handling unit processes the air by air filtration, cooling, dehumidification and temperature control.

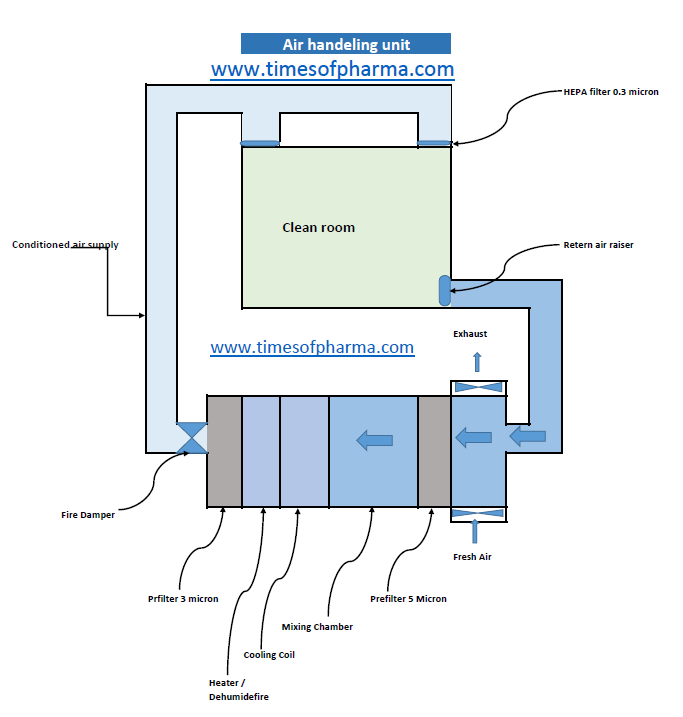

Purpose of AHU is to provide clean air that meets the requirements of clean room classification as per ISO.

Air is filtered, dehumidified, cooled and temperature controlled and supplied in a clean room through HEPA filter, which maintains the cleanness of the clean room with respect to microbial quality as well as level of and particulate matter.

Air required to be supplied in the clean room must be clean equivalent to the cleanness of the rated clean room, or should be of greater cleanness quality than the cleanroom, so that the air itself does not add to the particles.

How to make Air particle free: AHU is fitted with a prefilter of 10 microns and intermediate filter of 3 microns through which air is filtered and passed over dehumidifier and the over cooling chamber, from there the air goes through duct and to inside the clean room.

HEPA filter: Just before entering the clean room the air is terminally filtered through HEPA filters of 0.3 micron, which can remove particles of 0.2 micron.

After passing through HEPA filters the particles in the air are removed to the extent of 99.97 %.

Air cannot be made free from particles, at least 10 to 50 particles per cubic meter is considered of greater cleanness for even injectable dosage form as well.

The duct made of galvanized metal sheets is covered with a nitrile rubber insulation sheet, to close any leakage from the duct and to prevent loss of cooling.

Any leakage of air passing through AHU and duct is closed with insulation and other techniques.

Air leakage egress from the bottom of the door is closed with door seals.

Design concept of an AHU Different parts of an AHU:

Ahu is designed considering the area of the clean room and the purpose of the clean room, what class area is required. More cleanness is required, more air changes are required to be provided, therefore CFM of the AHU increases, size of the AHU increases, and vice versa.

The supply is done through roof and from side wall at bottom duct openings with filter in place are made for air to return through this duct to ahu.

Fresh air damper:

Fresh air is taken inside the AHU is filtered and supplied to clean room through HEPA filters,

Pre filters: Pre filters are placed in the return air risers for return air risers 10-micron pore size filter is placed. Also inside the AHU where the returning air and the fresh air enters in to the AHU.

Objective of the pre filter is to remove the coarse particles from air up to 3 microns.

Post filter: Post filters are placed at the outlet of the AHU box the cooled and dehumidified air is filtered through these filters these filters are of size 3 micron.

Terminal HEPA filters: Filter the air entering inside the clean room, HEPA filter removes almost 99.997 % of the particulate matter of the size 0.3 micron and above.

Blower: Blower is required to blow the air through filters and through the ducts and subsequently through HEPA filters. Blower is placed on the casing of the frame of AHU firmly.

Cooling coil: Cooling coil is coil cools the air and temperature of air is brought down, to comfort level, when cooling of air occurs, lot of moisture in the air too get deposit in the form of droplets inside the AHU wall, the water collected due to moisture from air is drained out through drain pan.

Heaters: Heaters are provided to bring back the temperature to desired temperature, heating works on the temperature sensors which starts heating of the ahu air up to a lower level of temperature.

Dehumidifier: Is an arrangement of heating and cooling of air which condenses moisture from air and drains away making air free from moisture.

Pressure gauze: The pressure gauzes are fixed at the entry of returning air to AHU and at the point of exiting from the AHU. To have an idea about the efficacy of the AHU. It helps in identifying leakage of air if any in the AHU casing and in the pre and post filters if any.

View panel to view inside of the AHU: Viewpoint with fiberglass to have visual observation inside the ahu is made.

Advanced systems in AHU: Fire dampers which cut off the supply of fresh air in the clean room in event of any fire in the clean room.

Cleaning of filters in AHU, how filters are cleaned:

Filters of AHU are cleaned periodically as per the frequency set in the SOP, during the cleaning of AHU filters clean room area is kept shut down, after cleaning of filters, decontamination by fogging with hydrogen peroxide and silver nitrate in very little concentration, and washing of the area is done followed by fumigation.

Validation of AHU: Validation is done by measuring the number of air changes, speed of motor and calculation of CFM is verified, during the validation of cleanroom.

Clean up time: Clean up time Clean room recovery test is established, while doing clean room validation, it’s time required to filter out and remove the particles from cleanroom to the acceptable level as per the limit of particles for respective clean room.

Decontamination of AHU: AHU and clean room is decontaminated by fogging Hydrogen peroxide dilute solution, in combination of silver nitrate a readymade stable ready to fog solution is available it also can be used. After fogging clean room and AHU, it is required to stand in position for at least 3 hours, after which AHU is started and the inner air is replaced, after the fogging, clean room is cleaned with water and soap solution followed by rinsing surfaces with purified water, and cleaning surfaces with dry lint free clothes.

Frequency of Decontamination of AHU and cleanroom is required to do every after 15 days. And depending on the settle plate count of the clean room, and microbial load of the air.

Leave a Reply