Compressed air gas for pharmaceutical manufacturing it’s limit for microbial count. for sterile product the Total Viable Bacterial count should be lesser or equal to 1 cfu/ cubic metre, and Total fungal count should be nil or not detected, the particle count of compressed air should equal to the at rest condition of the respective clean room, the one colony identified, the bacteria present there should be identified and ensured that it is not pathogenic.

Sampling of Compressed air Pharmaceutical for microbiological assessment.

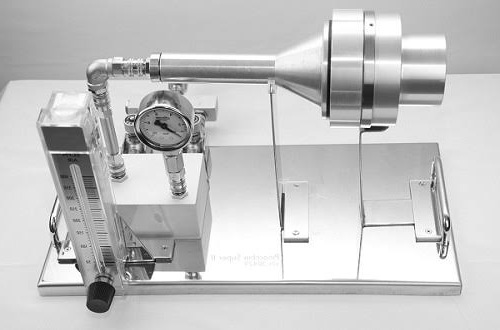

Due to pressure of compressed gas actual viable microorganisms may not get sampled during sampling of the gas, therefore the pressure is reduced to normal pressure and gas is flown over agar plate through an opening like a slit.

During manufacturing of pharmaceuticals compressed gas is required for operation of machines valves and many things, sometimes compressed gas like nitrogen gas is used for overlaying product surfaces, like in case of injections and sterile dosage form sterile powder for injection, and in liquid dosage form for overlaying the liquid oral product that otherwise may get exposed to environmental oxygen and degrade faster, there nitrogen gas is overlaid , therefore it is required to be free from extraneous matter like.

1)Particles.

2) Endotoxins, pyrogen free. Where gas is going to be part of a sterile drug product.

3)Bacterial and fungal contamination

4) Moisture.

Purity of Nitrogen gas required is more than 99%. It should be oil free

There should not be more than 1% to 1.5 % other gases in the gases used for pharmaceutical use.

Before direct contact of compressed gas with pharmaceutical products, it is filtered through a 0.2 micron air filter and dehumidifier, which removes the entrapped humidity during compression of the gas. There are more fine filters of size 0.1 micron are available one can additionally use such filters to have added assurance.

Nitrogen gas is in the form of compressed gas during compression of gas water molecule get into the gas and are compressed along with gas, and when they leave the port sudden expansion and cooling caused by gas render the water condense over the surface of the nozzle it is a risk of contaminant grow in the condensate which when enter in to a sterile dosage form can pose a serious risk to product. Therefore, before using the compressed nitrogen gas for the overlaying as an inert environment in sterile dosage form.

Also the moisture in the gas can contaminate the clean room specially of class 100 or Class A where the sterile drug product is filled into sterile containers.

How to evaluate microbial load in the. As per the US FDA guidelines 2004 FDA Aseptic Filling Guidance document the particle count of the inert gas should be lesser than or equal to the area in to which it will be used, that means it should not contaminate the product with its over loaded particles, here the particle count should be considered for at rest condition of the manufacturing area where the gas will be used. Compressed Gas for pharmaceutical use should be produced in the same environment as that of a clean room where it will be used in the product.

Reference: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=111.2

Leave a Reply