Category: Air handling Unit

-

What is Air handling unit

What is Air handling unit? Air handling unit is a part of HVAC system (Heating ventilation and air conditioning system)Air handling unit processes the air by air filtration, cooling, dehumidification and temperature control. Purpose of AHU is to provide clean air that meets the requirements of clean room classification as per ISO. Air is filtered,…

-

Clean Room Validation Recovery test

How a recovery test is done during validation of AHU/clean room in pharmaceutical manufacturing? Recovery test in AHU or clean room validation is a test where the ability of the clean room or AHU to maintain the level of cleanliness or the particle count below the rated classification limit. In the process clean room is…

-

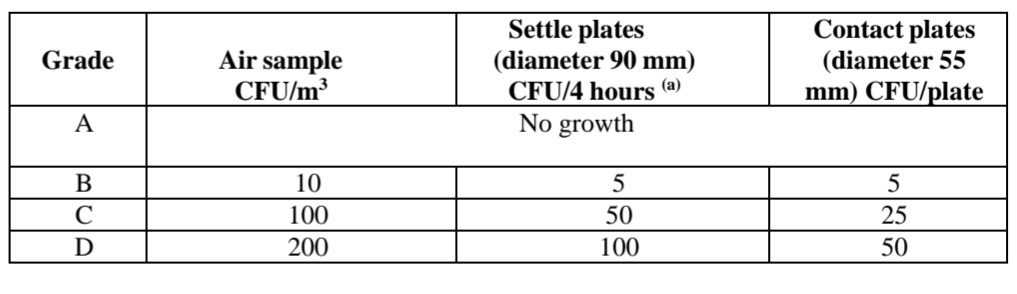

Clean Room Validation Microbial Count Limits

Clean Room Validation Microbial Count Limits method settle plate contact plate viable bacterial fungal count limits frequency of validation. Classification of clean rooms in pharmaceutical manufacturing companies is part of validation activity, a clean room is designed to provide the desired level of clean grade environment. but it’s rated only to a particular grade after…

-

Clean room classification In Pharmaceutical Industry Guidelines

Clean Room Classification in pharmaceutical Industry how it is done?. What is a clean room and clean room Classification in Pharmaceutical Manufacturing? Which are the different requirements of clean room class in pharmaceutical manufacturing ? Relation of Particle count and Viable Count requirements of different grades of Clean Rooms. Clean rooms in pharmaceutical industry are…

-

Pharmaceutical Area classification WHO guidelines

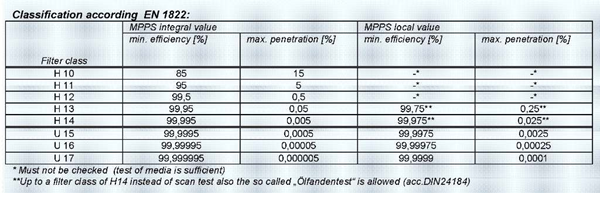

Pharmaceutical Area classification with respect to filters used as per WHO guidelines WHO gmp guidelines describes area in a pharmaceutical Manufacturing facility, as Level 1 level 2 and level 3 areas. Level 1 Area is place where there is no possibility of contamination of product, the product comes here after final packing if at all,…

-

Air Lock Types of Airlock Sink Airlock Cascade Bubble Airlock Types of Filters Clean up time

Air lock: Air lock is a system formed in the form of a small room which has entry in and exit doors, entry doors are kept open while exit doors are kept closed. Air flow is controlled in the room so that it prevents contamination of air of inside clean room of higher level of…